Our experienced team combines rigorous engineering discipline with lean, agile management practices to guide complex projects with clarity and confidence. We focus on building strong stakeholder alignment and ensuring every decision contributes to long-term success.

Our expertise includes:

- Concept ideation and validation

- Requirements elicitation and management

- Risk identification and mitigation

- Strategic architecture and systems design

- Stakeholder engagement and collaboration

- Lean project and program management

- Investment readiness and commercial planning

We partner with clients from ideation to launch providing the expertise to move confidently through every stage.

We take a systems-level view of every project, balancing innovation, practicality, and commercial realities. From concept through to delivery, our approach integrates technical excellence with strategic oversight to ensure the right outcomes at every stage.

By combining the expertise of Exa’s in-house Mechatronics Engineers with seamless partnerships across industrial design and our trusted supply network, we create highly integrated mechanical solutions that perform in the real world.

Our approach blends precision engineering with design thinking to ensure every component, from enclosures to moving parts, is optimised for function, manufacturability, and user experience.

Our expertise includes:

- Electro-mechanical systems and integration

- Product enclosures, including ruggedized devices

- Test rigs

- Antenna integration

- FDA Class I, II, and III medical devices

Our expertise includes:

- Electro-mechanical systems and integration

- Product enclosures, including ruggedized devices

- Test rigs

- Antenna integration

- FDA Class I, II, and III medical devices

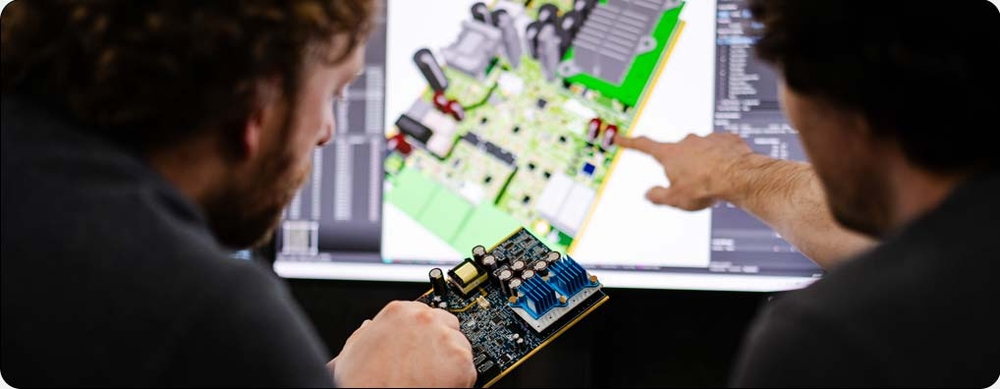

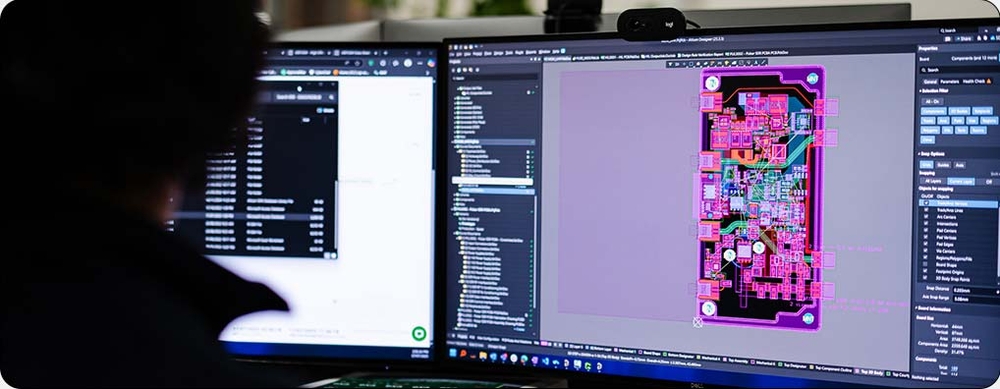

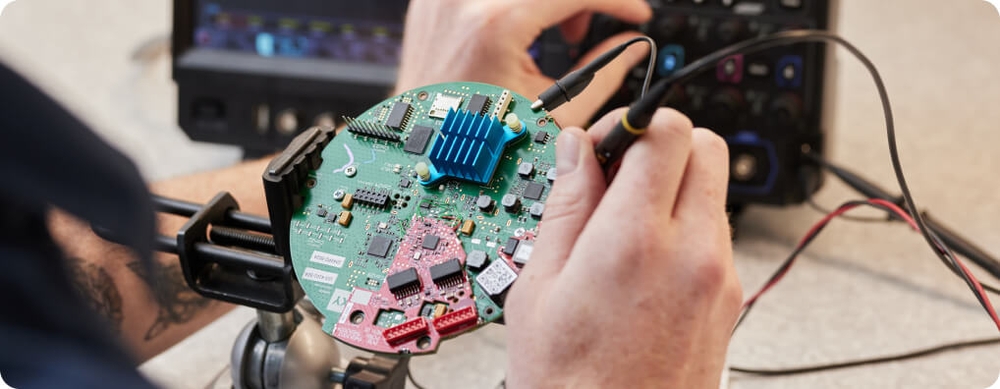

We excel across the full spectrum of electronics design, from early feasibility and prototyping through to EMC and safety compliance. Our team delivers robust, reliable designs that meet the highest technical and regulatory standards.

We apply a systems mindset to every stage of development, ensuring your product performs efficiently, safely, and at scale.

Our expertise includes:

- Power electronics

- Battery-powered systems

- Precision analogue design

- Flexible and rigid-flex circuits

- High-density interconnect (HDI) design

- High-speed digital systems

- RF and microwave design

- IoT hardware development

- Space and satellite applications

- Wireless communications

- Development of production test systems

Our expertise includes:

- Power electronics

- Battery-powered systems

- Precision analogue design

- Flexible and rigid-flex circuits

- High-density interconnect (HDI) design

- High-speed digital systems

- RF and microwave design

- IoT hardware development

- Space and satellite applications

- Wireless communications

- Development of production test systems

With a deep understanding of embedded systems and an integrated approach to development, our Firmware Engineers design and implement the right technologies to meet your product’s unique requirements.

From low-level control to complex operating systems, we ensure your hardware, firmware, and software work seamlessly together to deliver performance, reliability, and scalability.

Our expertise includes:

- Bare metal programming

- C / C++development

- Python scripting and automation

- Real-time operating systems (RTOS)

- Embedded Linux environments

Our expertise includes:

- Bare metal programming

- C / C++development

- Python scripting and automation

- Real-time operating systems (RTOS)

- Embedded Linux environments

Our Software Engineers have extensive experience across major platforms for operating systems, cloud, and mobile devices. We design secure, user-centred, and scalable software solutions that integrate seamlessly with connected systems.

By leveraging modern development platforms and continuous integration practices, we collaborate closely with clients and partners to build reliable, future-ready digital products.

Our expertise includes:

- Cloud architecture and deployment

- Web and mobile application development

- Distributed systems and IoT integration

- Secure and scalable APIs

- CI/CD and DevOps practices

- Software as a Medical Device (SaMD)

Our expertise includes:

- Cloud architecture and deployment

- Web and mobile application development

- Distributed systems and IoT integration

- Secure and scalable APIs

- CI/CD and DevOps practices

- Software as a Medical Device (SaMD)

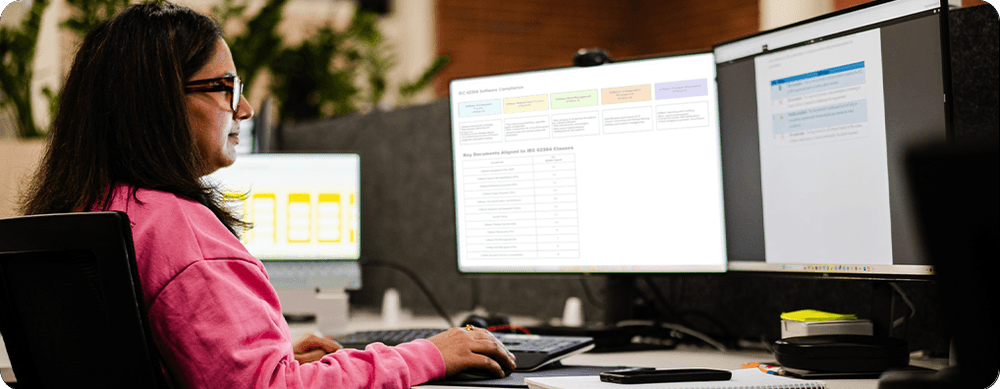

Get to market faster and with less risk. Our deep industry knowledge and strong partner network help you understand your regulatory responsibilities and streamline the path to compliance.

We guide you through complex certification processes, ensuring your product meets international safety and quality standards with confidence.

Our expertise includes:

- ISO 13485

- IEC 62304

- IEC 62368-1

- IEC 61010-1

- IEC 60601-1

Our expertise includes:

- ISO 13485

- IEC 62304

- IEC 62368-1

- IEC 61010-1

- IEC 60601-1

Ensure quality, efficiency, and repeatability in every stage of development. Our in-house electronics lab, extensive range of test equipment, and proven processes allow us to verify product performance with precision and confidence.

We develop clear testing protocols and automation solutions that validate functionality, reliability, and integrity, giving you complete assurance that your product meets its requirements before it reaches market.

Our expertise includes:

- Design for Test (DFT)

- Functional and performance testing

- Environmental and stress testing

- Test protocol development

- Automated test systems

- Compliance and certification support

Our expertise includes:

- Design for Test (DFT)

- Functional and performance testing

- Environmental and stress testing

- Test protocol development

- Automated test systems

- Compliance and certification support

We always begin with the end in mind. With extensive experience designing and preparing products for small, specialized, and large-scale manufacture, our team ensures every detail is ready for efficient, repeatable production.

We collaborate closely with you to optimize the transition from prototype to production, reducing cost, risk and time to market.

Our expertise includes:

- Design for Manufacture (DFM)

- Resource planning

- Development of production test systems

Our expertise includes:

- Design for Manufacture (DFM)

- Resource planning

- Development of production test systems

We take a systems-level view of every project, balancing innovation, practicality, and commercial realities. From concept through to delivery, our approach integrates technical excellence with strategic oversight to ensure the right outcomes at every stage.

Our experienced team combines rigorous engineering discipline with lean, agile management practices to guide complex projects with clarity and confidence. We focus on building strong stakeholder alignment and ensuring every decision contributes to long-term success.

Our expertise includes:

- Concept ideation and validation

- Requirements elicitation and management

- Risk identification and mitigation

- Strategic architecture and systems design

- Stakeholder engagement and collaboration

- Lean project and program management

- Investment readiness and commercial planning

Our expertise includes:

- Concept ideation and validation

- Requirements elicitation and management

- Risk identification and mitigation

- Strategic architecture and systems design

- Stakeholder engagement and collaboration

- Lean project and program management

- Investment readiness and commercial planning

How we work

Every project is different, so we shape our approach to meet each client’s goals, combining structure and flexibility to deliver results that last.

Our multi-disciplinary team works across the entire product journey, guiding strategy, design, engineering, and production to ensure every idea is realized with clarity, quality, and impact.

01.

Business Case & Research

We take the time to thoroughly understand your business case and help you to define your product. This helps to clarify how we can best support you as your development partner.

02.

Discovery & Planning

This formative phase underpins successful commercial development. We help you build a comprehensive foundation that asks questions today to avoid problems tomorrow.

03.

Design Strategy & Development

Our team plays an integral role across all design iterations and testing of your product. Our comprehensive planning and documentation protocols avoid unnecessary roadblocks and help keep your development on budget and schedule.

04.

Production Transfer

Together, we’ll establish a clear Production Transfer Plan, covering every aspect of production, from supplier selection through to final product acceptance. Leverage our global network and experience to streamline your production ramp.

05.

Production Improvements

Changes can occur over time that require product improvements or adjustments – from part availability to production changes. We can support your business in planning and responding to evolving needs.